Saturday, December 27, 2014

High Speed Rail

Amtrak's Acela Express is the first high-speed rail in the US. It travels on a ROW largely designed by a private railroad in the 1950s. It attains speeds up to 155 mph and connects Washington, DC to Boston via Baltimore, Philadelphia, New York, New Haven, and Providence. Total distance: 308 miles. Total ridership: 3.4 million. Total profit: $178 million. (Note the $178 million profit number includes state subsidies)

The catch is that this train runs through the major population centers of the US: Washington/Baltimore - 9M, Philadelphia - 7M, New York/New Haven - 23M, Boston/Providence - 7.9M. I'm using Combined Statistical Area since the other statistics seem to have more overlap (i.e. double-counting of population). So the Acela runs 308 miles through a population of roughly 47M people (152,000 people per mile) and gets about 3.4 million to ride each year at a profit of $178 million per year.

The next two most-talked-about potential high-speed rail corridors are the Texas Corridor and the California Corridor.

The Texas Corridor is 240 miles and runs between Dallas (6.8M) and Houston (6.1M). That's only about 55,000 people per mile. If the $178M in "profit" (remember those subsidies) were scalable, the project could expect revenues in the ~$65M per year range. With a cost of $10 Billion, the simple payback on this project would be 154 years.

The California Corridor is 800 miles and runs between Sacramento (2.4M) and San Diego (3M) by way of San Francisco (8.1M) and Los Angeles (17.9M). That's only 40,000 people per mile...and you can see where this is going.

For comparison, projects in the private sector generally require 2-5 year simple paybacks. Federal projects want a 10 year simple payback at most. This Texas thing will prove to be a most interesting development. If they're able to make a go of it and things turn out better than I expect, high-speed rail might become a reality! (I'm not holding my breath, though...)

Sunday, October 19, 2014

Inspirational Layout Themes

Sadly, I still haven't settled on a plan or theme for my layout; something the "Achievable Layouts" series was supposed to help clarify. Since I cannot find the time to create separate posts for each theme, I'll just summarize the themes I had in mind here. Mike Cougill has written an interesting piece on how he selected his layout theme, which sort of spurred this post.

Theme 1 - Illinois Central Hickman District. The Hickman District ran 51 miles from Dyersburg, TN to Hickman, KY. Once out of Dyersburg, the line served several farming communities and a large cottonseed oil mill at Tiptonville, TN. Power for the line was IC #610, a little EMD SW-1. Today, the line still exists as the TennKen railroad. Were I to model this line, I'd focus on modeling Tiptonville as there wasn't much beyond this point on the line. The Obion River had a swing bridge that would make for a signature scene. Dyersburg would also make a neat town to model, but the IC had a double-track mainline through there, a mid-size yard with roundhouse and an interchange with the GM&O. It's a bit much to pull off in anything larger than N scale.

Theme 2 - Columbus & Greenville post-1975. The Columbus & Greenville covered 151 miles between its two namesake towns. After 1975 there were several changes that added and subtracted from that mileage, but the railroad managed to keep running between these two towns until a washout in 2001 severed service. There are several towns along the line worth modeling: Columbus, Greenville, Greenwood, Winona, and Indianola being the primary ones. The major industry on the line is the catfish feed mill at Heathman, MS (just west of Indianola). Only Winona and Indianola are truly manageable from a modeling standpoint. The CAGY spun up with a fleet of Baldwin DRS-6-4-1500s and EMD SW-1s, but added some ex-FEC GP-7s in 1978 and later added ex-Southern GP-9s, ex-CNW GP-7s and ex-Santa Fe CF-7s. Even later, more ex-Southern GP-38s rounded out the fleet.

Theme 3 - Bonhomie & Hattiesburg Southern. This line was bought by the Tatum Lumber Company when the M&O sought to abandon their Hattiesburg Branch. The B&HS was famous for running steam until 1961. When they dieselized, they did so with two ex-Wabash SW-1s. I know very little about the industries on this line, but there may not be much to know. When the line was absorbed by the Illinois Central Gulf merger in 1972, almost 70% of its traffic was overhead traffic.

Theme 4 - Fernwood, Columbia & Gulf. This line was built by the Enochs Lumber Company and ran between Fernwood, MS and Columbia, MS. Power came in the form of an EMD SW-900 and an SW-1 (starting to see a theme here?). The SW-900 was the "road power" while the SW-1 switched the mill in Fernwood. On heavy trains out of Fernwood, the little SW-1 would couple to the rear and push the train out of the Bogue Chitto River bottom. The line connected the IC at Fernwood to the GM&O at Tylertown and the IC and GM&O at Columbia. When the ICG merger was proposed, the line stood to lose 60% of its traffic. For me, a model of the FC&G would include Fernwood, Tylertown and the grade in-between.

Theme 5 - Meridian & Bigbee. This line was built in 1928 and connected Meridian, MS with Myrtlewood, AL; but never really amounted to much until the paper mill at Naheola,AL was built in 1957. The line dieselized with a GP-7 and a GP-9. They picked up an ex-IC GP-7 in 1964 and several more Geeps and a CF-7 in the 1970s and 80s. The railroad interchanged with the Southern, GM&O and IC at Meridian; the Frisco (AT&N) at Riderwood, AL and the L&N at Myrtlewood, AL. The signature scenes are the paper mill and one-lane highway/rail drawbridge at Naheola, the depot and interchange at Riderwood, and the yard at Meridian.

Theme 6 - Gulf & Mississippi. A 713-mile spinoff of the ICG, this railroad only lasted from 1985-1988. There's plenty of opportunities for modeling, but the areas that would interest me most would be Starkville, MS; the West Point-Aberdeen line; the operations around Corinth, MS and the Middleton, TN to Woodland, MS section that required trackage rights to reach. The railroad operated with 30 ex-ICG GP-10s (and maybe a few GP-8s), but leased ex-Conrail GP-38s and ex-BN SD-45s. Four of the GP-10s were repainted in a very attractive G&M paint scheme. The train that operated over trackage rights used a caboose.

Theme 7 - Mississippi Delta Railroad. This line was spun-off from the ICG in the mid-1980s and operated by Gulf & Ohio railways to serve the large cottonseed oil mill in Jonestown, MS. I think they handled some contract switching for ICG in Clarksdale as well when ADM's soybean oil mill was in operation and Cooper Tire shipped by rail. This line is still in existence, but is now owned by a rail cooperative and operated by an independent. In the 1980s, they used ex-ICG units, two GP-10s and a GP-8. Today, they use a couple of ex-C&G CF-7s. The cottonseed oil mill at Jonestown would be the signature industry to model on this line. Otherwise, a few of the industries at Clarksdale would be interesting to model, but the declining traffic on this line renders it just a switching railroad.

Theme 8 - Illinois Central at Helena, AR. This was IC's only track in Arkansas and operated until the 1970s via a ferry connection. This would essentially be a switching railroad, but would allow me to model the IC's river operations as well. Lack of information on the industries served as well as the status as a switching railroad have caused my interest to wane.

Theme 9 - Illinois Central at Grenada, MS. Grenada was still a hopping place post-1967. IC still ran two passenger trains through town (the Panama Limited and City of New Orleans), but no through freights unless they were detouring off the Tallahatchie District. However, Grenada was the terminus for the Grenada-Durant turn, the Memphis-Grenada turn, and had a Water Valley-Canton local (41/42) that came through town but only stopped to pick up cuts of cars. A switcher worked a yard north of town, a few industries in-town and along an old Y&MV branch line. Train interactions would be THE attraction to Grenada. I've spent some time designing a layout to depict Grenada, but it's almost impossible to fit everything in HO scale, much less my preferred S scale. Not to mention the amount of equipment needed to pull this one off!

Theme 10 - Memphis Parkway Yard. This yard served the adjacent Ford Motor Company assembly plant, International Harvester and General Electric. Additionally, there were multiple small industries that shipped by rail. The line was switched by reciprocal agreement between the Illinois Central, Missouri Pacific, Cotton Belt and Frisco on quarterly shifts. The Illinois Central covered Cotton Belt's portion of the agreement, meaning you had six months of IC and three months of Mop and Frisco. This would be an all-switching layout and an intercity one at that. While I do call Memphis my hometown and the opportunity to model three railroads is tempting, I can't bring myself to build a layout that wouldn't have any trees. Sure, I could fudge a sapling in here or there, but this was down-and-dirty city railroading.

Theme 11 - Mississippi & Skuna Valley. The little line was owned by the Bruce Lumber Company (later Weyerhaeuser) and ran from Bruce Junction (just south of Coffeeville) to Bruce, MS. The line operated with a 70-tonner in the early 1970s, picked up an ex-Penn Central SW-9 and an ex-Santa Fe CF-7 which it used until abandonment in 2011. The major customer was the Weyerhaeuser, but the line also served a furniture plant, a propane dealer and a grain silo in Bruce. Otherwise, there were no other industries on the line. This would essentially be a switching railroad centered on Bruce, MS.

Those eleven themes all have their strong points and negative points. The trick for me is to determine what elements of these themes cause me to want to model them. Perhaps the answer of "What to model?" is not a matter of picking a single theme, but combining elements of multiple themes in a plausible way. Any thoughts you have would be appreciated!!

Saturday, September 14, 2013

Texas Transportation Company

Here's a few photos and video to get you going:

TXTC#1

TXTC#2

Don Ross's site

Video 1

Video 2

From what I can tell, it looks like they had inbound loads of corn syrup, hops and probably some packaging materials. Beer is the most obvious outbound load, but apparently the local glass company shipped a load of plate glass from time-to-time. The signature structures along this line would have to be the Pearl Brewery building (with rotating sign), the Pearl stable building (the oval building in the photos), and the Pearl bottle houses (the two buildings that form the alleyway in this photo). From the brewery, the railroad ran down the middle of Jones Avenue alongside the old Lone Star Brewery, which has housed the San Antonio Museum of Art since the 1970s. The last signature structure would be the truss bridge that spans the SP-TXTC interchange tracks.

If I were to model this railroad, I'd set it in the 1990s and do it along three walls. From left-to-right going around the room: The first wall would be the SP interchange with the bridge and a few warehouses/industries along the backdrop. At one time (1960s and earlier?), these industries were served by the traction railroad. If I wanted to add a little more operation, I might add a few car spots to the interchange track nearest the buildings. The second wall would be street running down Jones Avenue. The Hwy 281 overpass would form the left boundary of this scene. I'd want the old Lone Star Brewery structure to form the backdrop, so I'd use a little modeler's license there to orient that structure along the backdrop. The third wall would be the Pearl Brewery scene. The I-35 overpass would form the left boundary of this scene. The tracks would immediately duck into the bottling plant area and come out into the brewery scene. One of the best things about this line is that a 24" radius in HO scale would be prototypically sharp!

A model appropriate for TXTC #1 has been made in almost every scale (including S!). TXTC #2 would have to be scratchbuilt. The rest of the freight car roster could be fleshed out using commercially available kits. Since the SP was the connecting railroad, plenty of options are available in all scales.

The railroad switched the brewery at least twice per day. I could definitely see inviting a few guys over and enjoying some switching operations while partaking a bit of the ladings! I wonder if I can find Pearl Beer in Alabama?

Monday, September 9, 2013

Achievable Layouts, Southern Style

Sunday, January 10, 2010

Over-Center Springs for Atlas Code 55 Turnouts

When it comes to turnout control, there’s a whole host of ways to accomplish the task: Tortoise machines, servos, ground throws, latch-bolt throws, solenoid machines, finger-flick, pushrods…and then there’s the combinations of these methods! To simplify things, I like to categorize these in terms of Electronic vs. Manual and Under-table vs. Topside-mount. Here’s the breakdown on how those technologies fit into my grid:

| Electronic | Manual | |

| Under-table |

|

|

| Topside Mount |

|

|

I initially bought some Caboose Industries ground throws, but their large size compromised the appearance of the code 55 track. Why go to the trouble of near-scale track only to butcher the look with an oversize ground throw? I would have been better off to use Peco code 55 and lived with the European tie spacing. While there have been some really good ideas to disguise the CI throw’s oversize appearance, I didn’t think this would work since my spline roadbed would basically leave the throws unsupported. I tried using electric toggle switches with linkages on my test bed layout. While simple enough, I’ve had some problems with the toggle throw being longer than the turnout throw. The turnouts on my test bed layout were soldered together, so they were able to handle the stress. I feared that the Atlas code 55 turnouts might not fare so well and there’s still that whole mounting thing. That left me with the finger-flick method with either a center-over spring or a friction pad. I tried doing a friction pad on the bottom of the throwbar, but worries of what would happen once the friction pad wore down kept me from pursuing this route. Still the friction pad is a great idea and is probably something I’ll consider again.

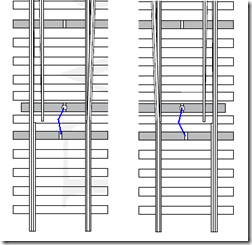

So a center-over spring it is! Atlas code 55 turnouts, unlike their Peco and Micro Engineering counterparts, do not have a center-over spring. No problem. I’ll just make one. Surely someone on the internet has a “how-to” to guide me. A search

revealed some verbal descriptions on a blog, but no pictures. I know it’s just three bends in a piece of wire, but someone should really do a video or something. For now, the diagram to the left will have to do. The idea is simple: moving the turnout from right to left causes compression in the spring (the blue line) until the throw reaches the midpoint. At the midpoint, the spring is under maximum compression. Further movement to the left will release compression on the spring, causing the points to snap to the left when the throw reaches the midpoint. The same compression occurs as the points are moved back to the right, causing the points to snap to the right once the throw moves past the midpoint on the right side. Since the compression tends to release itself once the throw is moved “over the center point,” these devices are called “over-center springs" or "center-over springs.” Below is a YouTube video on how I made center-over springs for my Atlas turnouts.

revealed some verbal descriptions on a blog, but no pictures. I know it’s just three bends in a piece of wire, but someone should really do a video or something. For now, the diagram to the left will have to do. The idea is simple: moving the turnout from right to left causes compression in the spring (the blue line) until the throw reaches the midpoint. At the midpoint, the spring is under maximum compression. Further movement to the left will release compression on the spring, causing the points to snap to the left when the throw reaches the midpoint. The same compression occurs as the points are moved back to the right, causing the points to snap to the right once the throw moves past the midpoint on the right side. Since the compression tends to release itself once the throw is moved “over the center point,” these devices are called “over-center springs" or "center-over springs.” Below is a YouTube video on how I made center-over springs for my Atlas turnouts.Saturday, November 14, 2009

DCC Controls for the HOG

The box is built out of aspen plywood and measures 19" x 10" x 10". While there may be some wasted space, it ain't much! The top photo shows the front of the box. On the front is a lockable case latch so a small padlock can be applied to the case to keep little hands out when it's time to go to lunch or peruse the train show. The second photo shows the end where a large computer fan draws in air and pushes it across the transformers and the booster. On the backside (third photo), you can see the piano case hinge for the box lid, the exit hole for the cooling air, and the standard computer plug that connects to the power supply. Using the removable power cord makes it very easy to transport. The last picture shows the business end with the Digitrax UR91 radio throttle receiver and four Cinch-Jones plugs. The Cinch-Jones connectors are the Ntrak standard, so this box can quickly be connected to any Ntrak layout.

Opening the box, there's a programming track and a tray to hold all of the throttles, power cable, and connector cable. This tray is also a safeguard against curious little hands that might find their way into the box.

Removal of the tray reveals the guts of the system: The DCS100 booster, the UR91 radio throttle receiver, and the PM42 power manager (all on the right). The booster is attached with heavy-duty velcro just in case it needs to be removed. The UR91 allows Digitrax simplex radio throttles to be used. The PM42 is particularly necessary for Ntrak layouts since it allows individual circuit breaker detection. This way, a short on one track doesn't cause a system crash and everyone else can keep running trains while the short is found. On the left, there are a couple of fuses and a circuit breaker for the power supply. Just plugging in the power cord does not power up the transformers. The switch on the far left has to be thrown first. Even that does not power up the booster; that's the purpose of the other switch. All exposed wiring on the right side of the box is either 12V or 16V, so there's no real shock hazard. Even at this level, I didn't want there to be any chance of a child getting shocked. Hopefully, someone will have spotted the little tike by the time he/she gets this far!!

Removing the partition and lifting the cover that contains the power switches and the circuit breakers shows the transformers. The terminal blocks on the left carry 110V power, so it's a good idea to have the box unplugged before even opening this side. The fan is a 110V fan, so it runs directly off the input power. The large transformer powers the booster, while the two smaller transformers provide power to the UR91 and the PM42.

And that's it! All in all, it's about the best way I've seen to make a full DCC system truly portable. Putting the system in a box sure cuts down on the clutter associated with the Digitrax system, so this might be a good idea for any Digitrax user. I hope these ideas are of some use to you...

Saturday, November 7, 2009

Adding the Fascia

Once the glueshell dried, I measured from the bottom of the benchwork to the top of the glueshell scenery at the layout edges. Just under 6” was the longest measurement, so I cut a 4x8 sheet of Masonite into 6” strips and attached them to the sides of the layout with clamps to temporarily hold them in place. Using a felt pen, I marked off the land contours by tracing along the joint between the glueshell and the fascia board. Cutting along the lines with a jigsaw yielded a nice fascia piece that matched to land contours:

You can see the holes that were drilled to allow the clamping bolts to pass through. I forgot to do this on one section before I attached them to the layout. Let’s just say that it really helps to pay attention to detail at this point! Once the contours were shaped, it was time to attach them to the layout with wood glue and clamps:

You’ll notice that I let the ends hang out over the corners of each layout section. These can be cleaned up with a flush-trim bit in a Roto-Zip after the glue dries.

One advantage of allowing the ends to hang out a bit is that you have a surface to leverage if the corners don’t come out EXACTLY square. I had this happen on the end piece in the photo below where I was lacking a 1/16” being flush with the adjacent piece at the corner. Using a bungee strap and the weight of the layout, I was able to pull against those long ends to take that 1/16” out and get a nice, flush fit:

After trimming with the Roto-Zip, here’s the layout with the fascia installed:

I also had to do a bit of cleanup with the flush-trim bit at the layout joints since some of my marks didn’t match up exactly. If you haven’t used one of these bits in a Roto-Zip or a router, they make quick work of the problem of cutting a corner piece exactly to length. I highly recommend giving one a try!