When it comes to turnout control, there’s a whole host of ways to accomplish the task: Tortoise machines, servos, ground throws, latch-bolt throws, solenoid machines, finger-flick, pushrods…and then there’s the combinations of these methods! To simplify things, I like to categorize these in terms of Electronic vs. Manual and Under-table vs. Topside-mount. Here’s the breakdown on how those technologies fit into my grid:

| Electronic | Manual | |

| Under-table |

|

|

| Topside Mount |

|

|

I initially bought some Caboose Industries ground throws, but their large size compromised the appearance of the code 55 track. Why go to the trouble of near-scale track only to butcher the look with an oversize ground throw? I would have been better off to use Peco code 55 and lived with the European tie spacing. While there have been some really good ideas to disguise the CI throw’s oversize appearance, I didn’t think this would work since my spline roadbed would basically leave the throws unsupported. I tried using electric toggle switches with linkages on my test bed layout. While simple enough, I’ve had some problems with the toggle throw being longer than the turnout throw. The turnouts on my test bed layout were soldered together, so they were able to handle the stress. I feared that the Atlas code 55 turnouts might not fare so well and there’s still that whole mounting thing. That left me with the finger-flick method with either a center-over spring or a friction pad. I tried doing a friction pad on the bottom of the throwbar, but worries of what would happen once the friction pad wore down kept me from pursuing this route. Still the friction pad is a great idea and is probably something I’ll consider again.

So a center-over spring it is! Atlas code 55 turnouts, unlike their Peco and Micro Engineering counterparts, do not have a center-over spring. No problem. I’ll just make one. Surely someone on the internet has a “how-to” to guide me. A search

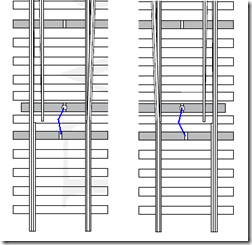

revealed some verbal descriptions on a blog, but no pictures. I know it’s just three bends in a piece of wire, but someone should really do a video or something. For now, the diagram to the left will have to do. The idea is simple: moving the turnout from right to left causes compression in the spring (the blue line) until the throw reaches the midpoint. At the midpoint, the spring is under maximum compression. Further movement to the left will release compression on the spring, causing the points to snap to the left when the throw reaches the midpoint. The same compression occurs as the points are moved back to the right, causing the points to snap to the right once the throw moves past the midpoint on the right side. Since the compression tends to release itself once the throw is moved “over the center point,” these devices are called “over-center springs" or "center-over springs.” Below is a YouTube video on how I made center-over springs for my Atlas turnouts.

revealed some verbal descriptions on a blog, but no pictures. I know it’s just three bends in a piece of wire, but someone should really do a video or something. For now, the diagram to the left will have to do. The idea is simple: moving the turnout from right to left causes compression in the spring (the blue line) until the throw reaches the midpoint. At the midpoint, the spring is under maximum compression. Further movement to the left will release compression on the spring, causing the points to snap to the left when the throw reaches the midpoint. The same compression occurs as the points are moved back to the right, causing the points to snap to the right once the throw moves past the midpoint on the right side. Since the compression tends to release itself once the throw is moved “over the center point,” these devices are called “over-center springs" or "center-over springs.” Below is a YouTube video on how I made center-over springs for my Atlas turnouts.